Who Wins The Tape And Reel Vs. Cut Tape War?

The electronics sector has advanced greatly in every way since the 1970s. New and innovative technology that increases cost-effectiveness and shortens manufacturing times at every level is readily apparent. Modern placement machines, which can pick and position thousands of components per hour with pinpoint accuracy, are one such example.

But one requires an equally capable component distribution mechanism to use this remarkable performance. The two main component distributors of product packaging are Cut Tape and Tape and Reel. Which of the two is superior for packing will be covered in this article.

Tape and reel vs. cut tape: Which should I choose?

A long, continuous piece of tape is wound onto a unique reel for tape and reel packaging. To supply electronic components to a pick-and-place device is its intended use. In the end, each carrier tape pocket will be filled with miniature electronic components. The machine can quickly populate the board by sealing them with heat- or pressure-sensitive cover tape.

Similar to tape and reel substitutes, cut tape packaging has a purpose. Since cut tape lacks a suitable leader and trailer, the process cannot be automated but securely delivers components to the client.

For most applications, tape and reel packaging are superior to sliced tape. The tape will automatically feed through the machine in a continuous feed with just one entry from the operator. This eliminates the inconvenience of manual placement for the manufacturer and lowers the possibility of human error.

Packaging with tape and reels also works well to avoid jams. Trying to automate cut tape frequently jams the machine and sticks inside the feeder. Contrarily, components that enter the machine on a reel prevent jamming.

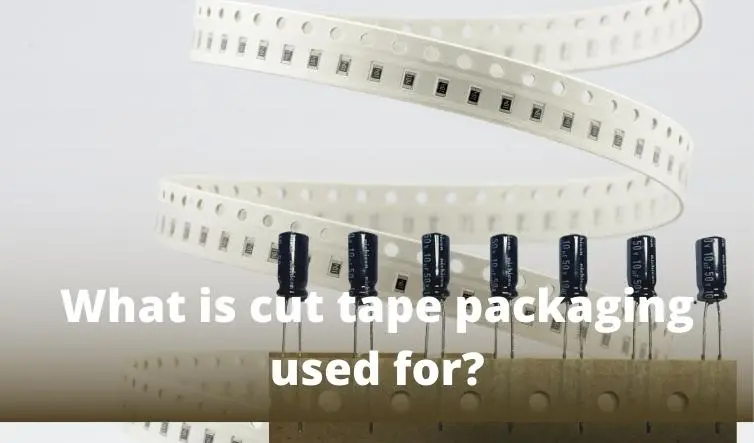

What is cut tape packaging used for?

There are specific circumstances in which packaging with cut tape is required. You must employ cut tape packaging if only a small quantity of a specific kind of component is needed for the board. To prevent further problems down the road, keep this in mind when acquiring your materials.

During board repairs, cut tape packing is also perfect for bespoke components. Use one piece of cut tape to make these adjustments if you’re only going to assemble one board or fix an already-built one. However, reel packaging is only necessary when numerous boards are assembled sequentially.

Tape vs. Reel: Which is better?

While “reel” is long, continuous, and wrapped up in a reel, “cut tape” distributes components in the form of brief cuts of tape. Although their application varies depending on the board being produced, the reel is typically a better and more popular choice. Time is reel packaging’s main advantage.

Cut tape vs. Digi reel

Both cut and reel use a tape containing components to deliver components into the pick-and-place device (usually small ICs). The length of the tape is the primary distinction, though. While “reel” is long, continuous, and wrapped up in a reel, “cut tape” distributes components in the form of brief cuts of tape.

What is the difference between tape and reel versus cut tape packaging?

While “reel” is long, continuous, and wrapped up in a reel, “cut tape” distributes components in the form of brief cuts of tape. Although their application depends on the type of board being put together, a reel is usually preferred for most pieces.

The tape’s length is the primary distinction. Although their application varies depending on the board being produced, a reel is typically a better and more popular choice. Time is reel packaging’s main advantage.

Reel provides for a single continuous feed while only requiring the operator to fill the feeder once, as opposed to 20 separate strips of tape. Additionally, operators are required by quality standards to notify quality control (QC) staff each time new components are added to a machine.

Lean principles state that this is wasteful. The reel also enables users to prevent jams. Cut tape occasionally gets stuck in the feeder, although reeled parts typically don’t. But the cut tape is important when only a small quantity of a particular component is needed for the board. It’s crucial to keep this in mind during the buying process.

Purpose of cut tape packaging?

Cut tape packaging serves a different purpose than tape and reel packing. For most applications, tape and reel packaging are best since it saves time and reduces the possibility of human error. For quick board repairs and modest builds, cut tape packing works well.