Does Solder Conduct Electricity?

Is solder a good electrical conductor? Soder is an electrical conductor, but simply it cannot be named as a good conductor of electricity. The electrical conductivity of soft and hard solders varies with composition between roughly 9% and 13% for soft solders and 20% and 40% for silver solders, which is significantly less than that of copper.

In this article, we focus on the electrical conductivity of the solder, and we discuss almost everything you need to know about the solder when using it for your purposes. So stick around until the end to find out what you’ve been looking for. Welcome to RLC Talk.

What is solder made of?

When heated to its melting point, a metal or metal alloy known as solder can connect two metal surfaces. A tin-lead alloy is a typical soldering compound, but there are others with different melting points and best applications. Thin, silver-colored wire of various thicknesses known as solder is most frequently sold in rolls.

What is the composition of solder? 60% tin, 39% lead, and 1% alloys are the most common ratios. This mixture melts and sets quickly, is strong, and has a narrow melting range. A higher tin content increases the corrosion resistance of the solder but also raises the melting point.

The most typical are typically a lead-and-tin alloy, but in the US, businesses that produce lead-free solder are eligible for a tax credit. Lead usage in electronics is severely constrained in the EU. Tin, copper, zinc, bismuth, antimony, iridium, and/or silver may be used in lead-free solders.

Other metals are available and are utilized less frequently. Copper is more frequently used by plumbers to solder copper pipes and tubing. Due to the lower melting point of tin, silver, and copper in Japan, electronics manufacturers frequently choose these three metals in combination.

Modernized versions of this mixture typically contain zinc or manganese as the fourth element. Silver solders are more expensive, less common, and are typically used in specialized applications.

What is solder used for?

There are many uses of solder in man fields. So the following are some of the uses of the solder

In eclectic circuits.

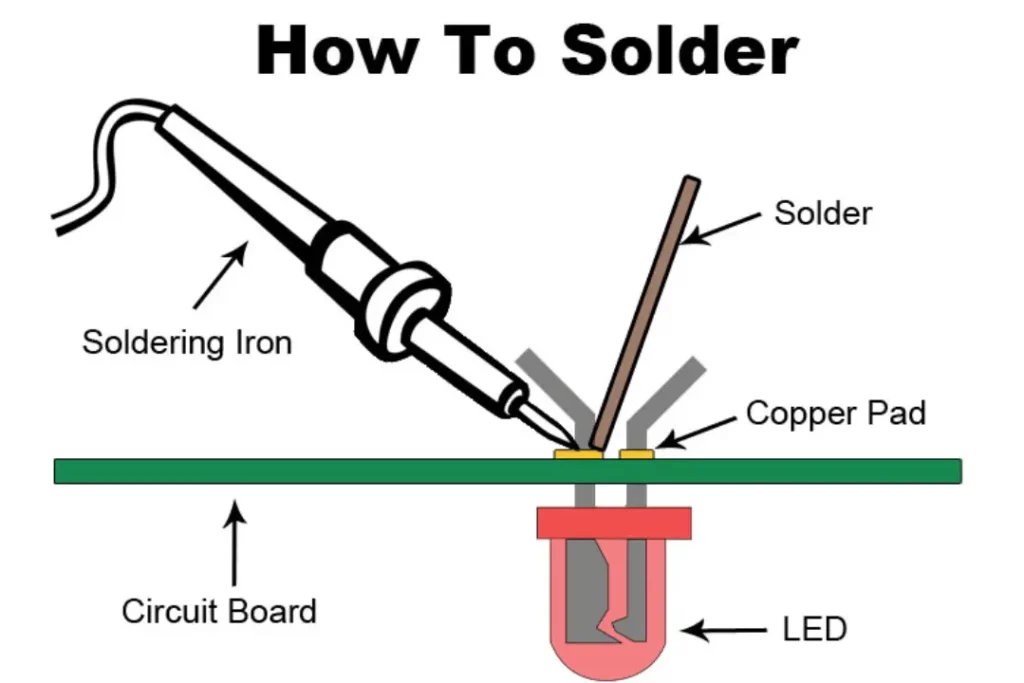

For electrical continuity, solder ensures contact between two wires. Solder also “locks” the wiring into place on the circuit board. Small solder joints frequently require the use of a soldering pencil that is connected to a power source so the user can regulate the temperature.

Electricity repairs.

When installing wiring in homes or businesses, electricians frequently splice wires together using solder. Wires are occasionally fused to electrical terminals inside electrical devices or on control panels using solder.

Solder is used to fill irregular cavities, smooth rough surfaces, and tighten joints but is not strong enough to repair engines. When performing auto body repair, it is also used to tin the edges of metal sheets, fill in holes, and fuse metal panels.

The conductivity of solder vs copper.

Both soft and hard solders have electrical conductivities that are significantly lower than those of copper, ranging in composition from roughly 9% to 13% for soft solders to between 20% and 40% for silver solders.

There are two main categories of soldering: soft soldering, which primarily uses tin-lead alloys, and hard soldering, which primarily uses copper-zinc alloys (brazing) or silver-copper-zinc alloys (silver soldering). In electrical work, soft soldering and silver soldering are both used to varying degrees; brazing is rarely used.

Is solder a good conductor of heat?

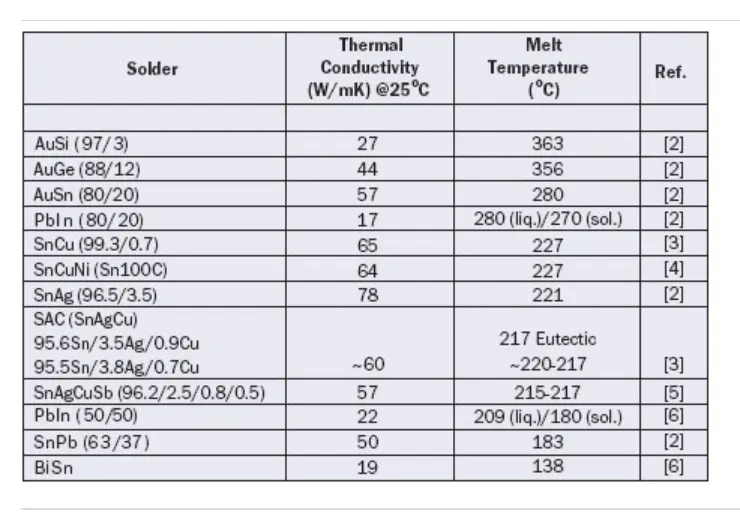

Eutectic alloys are those solders with a single listed melting temperature. The constituent elements are listed in the first column, along with the percentage of each element, in parentheses. It should be noted that while elements making up 5% or less of an alloy may vary by up to 0.2%, those making up 5% or more may vary by up to 0.5%.

In hermetic packages, the high melting-temperature solders listed at the top of the table are frequently used for die attachment.

In order to prevent excessive stresses when the assembly cools down and these higher melting point solders are used, substrate materials with a coefficient of thermal expansion closely matched to the semiconductor are typically used.

One frequently employed die to attach solder, gold-tin eutectic solder has a number of advantageous properties but is relatively pricey.

Does solder flux conduct electricity?

Yes, flux can be conductive and have an impact on the performance of your fine-pitch component. The majority of PCB manufacturers clean their products by rinsing with warm DI water and water-soluble flux. Additionally, there are numerous flux removers for various types of flux available online. Try looking around stores that sell electronic supplies and equipment.

Using acid, solder flux removes metal oxides; acidic substances, like solder flux, contain both hydrogen ions and negative ions. Ions can conduct electricity, so the solder flux transfers these conductive ions to the component that needs to be soldered.

The conductivity disperses and reduces the efficiency of the electric currents when solder flux residue is left behind. Additionally, a lot of conductive material will make your electronics extremely unstable.

Is rosin core solder conductive?

Rosin (R) flux is a rosin and solvent mixture best suited for smooth, simple-to-solder surfaces. Rosin has a high corrosion resistance, is hard, and is not conducive.

Rosin (R) flux is a rosin and solvent mixture best suited for smooth, simple-to-solder surfaces. Rosin has high corrosion resistance, is hard, and is not conducive. Rosin flux remnants may be removed with a compatible solvent or left on the assembly.

- Massive wires.

- Merely thoroughly clean and solderable surfaces.

How Can Solder Flux Remains Be Cleaned?

When finished soldering, it is usually essential to remove any remaining solder flux. This is due to the possibility of other components of the device being harmed by excess solder flux residue, which can also cause conductivity and low voltage insulation shorts.

Additionally, extra solder flux residue leads to current leakage, which reduces the efficiency of your electronics.

While rosin-based solder fluxes may need a specific cleaner and water-soluble solder flux residue can sometimes be cleaned with hot water (if done quickly enough), solder fluxes can generally be cleaned as follows:

- Use acetone or isopropyl alcohol to soak an old toothbrush. Remove any extra toothpaste from the toothbrush.

- Cross the solder flux with the toothbrush that has been covered in acetone or alcohol. Avoid handling this roughly because doing so could break the solder point.

- Continue with step two until all traces of solder flux are gone.

- Last but not least, clean up the area with a fresh napkin or towel and let it air dry. Use canned air to make sure there isn’t any solder flux dust present.

Does solder increase resistance?

Yes, theoretically. Actually, no. Why no? Even though solder isn’t quite as good of a conductor as copper, there is still a lot more solder used in a soldered joint than there is copper wire.

It’s highly likely that a thick blob of solder has the same low resistance as the thinner copper wire. Additionally, because the path through the solder is so brief, any difference in resistance is probably unnoticeable.

How to be safe while soldering?

The soldering iron’s element must never be touched while soldering. Clamps or tweezers must be used to hold the wires in place.

Make sure the cleaning sponge is kept at all times while being used. When not in use, the soldering iron must always be put back on its holding stand.

You must always keep it up off the workbench, and when not in use, the device must be unplugged and turned off.

When possible, use lead-free solders or rosin, and make sure to wear eye protection. After soldering, wash your hands thoroughly with soap and water, and keep the cleaning solvent in the dispenser bottles.

Some related FAQs.

What is the most conductive solder?

What do you mean by 60-40 soldering?

It is advised to use iron tips at temperatures of at least 300 °C. It is also very soft, so if the joint moves while cooling, cracks won’t appear as quickly.

Does solder have a voltage limit?

Heating will put a limit on the current. The conductivity of 60/40 solder is 11.5% that of copper, per this Multicore datasheet.

How much force can a solder joint hold?

Is a solder stronger than a weld?

The strength of the connection created by soldering depends on the solder you use.

Without specialized tools and methods, it is typically impossible to weld two different metals together.