How To Remove Solder Without Wick?

By heating a filler material called solder as well as applying it to the connection, a procedure called soldering is employed to bind two metals permanently. In addition to utilizing a solder wick, there is a number of alternative ways to remove excessive solder. How to remove solder without wick? Let’s investigate.

What is Desoldering?

To detach or replace elements in an electrical circuit, you must first desolder that joint where the solder has been applied. This is frequently required when maintaining or altering an electrical item or when changing out a faulty component.

What purpose serves wick have?

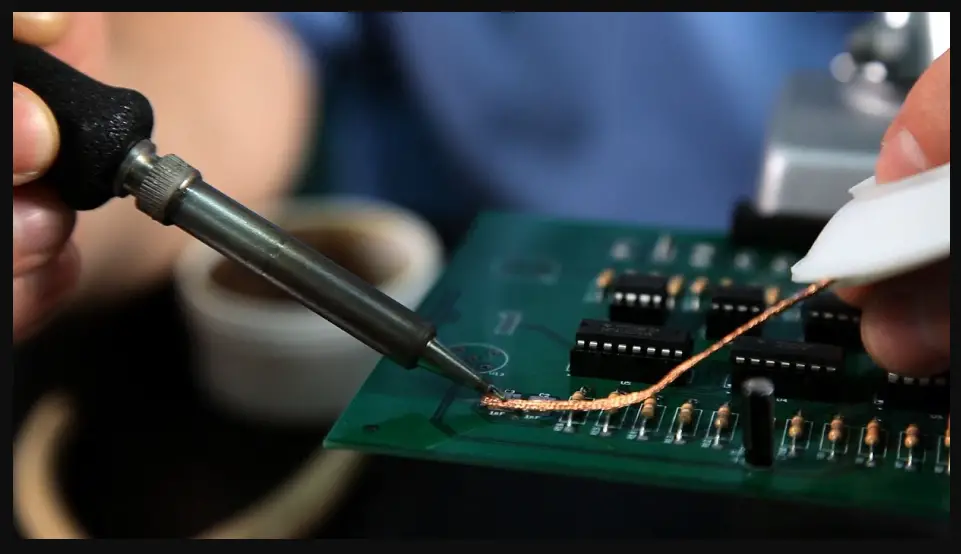

A copper wire that has been braided and covered with flux is referred to as a soldering wick while soldering is being discussed. A soldering iron is used to heat its wick after it has been put over a junction with extra solder. The excess solder is successfully removed from the junction by melting and flowing through into the braid as a result of heat.

How can I use a wick to remove solder?

These are the procedures for utilizing a wick as remove soldering.

Above the joint, position the wick

- Place the wick in such a way that the flux-coated section is immediately above the junction where the extra solder is present.

Warm up the joint

- The junction should be heated with a soldering iron till the solder melts and becomes liquid.

Bridge the junction with the wick

- Spread the wick over the junction carefully once the solder has melted. Molten state solder would be drawn through into the wick by the flux inside the wick.

Make the junction clean

- After removing the surplus solder, please clean up the junction by wiping it down with a clean, moist, damp cloth and wiping away any leftover flux.

Examine and test

- Check the junction to make sure that any extra solder has now been withdrawn and, as such, the item or PCB has not been harmed. Conduct functionality as well as continuity tests.

Can solder be removed without a wick?

Yes, solder may be eliminated without the use of a wick. So, how to remove solder without wick?

How to remove solder without wick? Methods.

Method 1: Desoldering with a Soldering Iron

The solder could be melted in a junction by applying heat using a soldering iron. Small quantities of solder could be removed with this technique, but it needs a high level of expertise and accuracy to prevent injuring the parts and the connecting wires.

Method 2: Make Use of a Desoldering Pump

By creating a vacuum, this device removes the molten solder from the junction. Although it can be challenging to utilize on fine-pitch parts and occasionally causes a piece to be pulled away well with solder, this technique is effective for extracting increasing quantities of solder.

Method 3: Making Use of a Desoldering Iron

With the help of a built-in suction pump, all melted glue is removed as the solder gets warmed inside this specialty soldering iron. The elements won’t be pulled out during desoldering thanks to the method’s efficiency and accuracy.

Method 4: Make use of a heated air gun

With this device, solder may be heated and removed more effectively from PCBs, including SMD parts.

Method 5: Desoldering Automation.

This technique automatically removes the solder by heating the connection with specialized components. Robotic soldering devices and reflow ovens are examples of this technology.

Soldering Not Melting: What Could Be the Reason?

rlc talk

A step-by-step guide to removing solder without wick

Desoldering with a Soldering Iron

- The junction in which the solder has to be stripped should be accessed with a desoldering instrument or forceps.

- If you’re employing a soldering iron to warm the junction, make careful to avoid any desoldering tools or tweezers as well as heat the joint.

- After melting the solder, gently peel it away from the junction using tweezers and desoldering tools.

Make Use of a Desoldering Pump

- The junction that requires the solder to be cleaned should be covered by the desoldering pump’s nozzle.

- Use a soldering iron to warm the junction, making it cautious to avoid heating the desoldering pumps there.

- A desoldering pump’s trigger should be depressed after the solder has melted in order to produce a vacuum and remove the solder from a connection.

Making Use of a Desoldering Iron

- The junction that requires the solder extracted should be covered by the desoldering iron’s point.

- Use the desoldering irons to warm the junction, making sure to keep any neighboring parts out of the area of heat.

- To remove the solder from the junction once it has melted, click the button to turn over the vacuum filtration that is already there.

Method 4: Make use of a heated air gun

- The junction in which the solder has to be dissolved should be covered by the hot air gun’s tip.

- Use the hot air cannon to warm the joint, making it cautious to avoid heating any of the elements nearby.

- After melting the solder, firmly peel the solder off from the junction with tweezers or even a desoldering device.

Method 5: Desoldering Automation

Making use of a Reflow Oven

- Enter the reflow oven well with circuitry that has the junction that requires the solder ever to be cleaned.

- Every solder alloy, as well as the elements here on board, should be matched with the oven’s heat parameters.

- Its solder would melt on the heated board inside the oven, flowing away out from the connection as a result.

- The parts are then fixed in their new location when the board has just been warmed as well as the solder has already been withdrawn.

Utilizing a robot-assisted soldering system

- Enter your robotic soldering equipment well with a circuit board that has the junction that has to have the solder separated.

- Its solder alloy, as well as the elements here on board, should be matched in the parameters of the robotic arm plus software.

- Its heating element would be positioned by the robotic arm well over the junction, searing the solder as it flows away out from the junction.

- Its robotic arm fixes the parts in their new location after removing the solder, as well as adjusts them if needed.

Whatever technique you choose, after you’ve completed all the processes, be sure to wipe the joint with a clean, wet sponge or towel to get rid of any fluxes and debris that could still be there. Check the junction to make sure that any extra solder has already been taken out and that the circuitry or elements have not been harmed.

Can you use petroleum jelly as soldering flux?

rlc talk

FAQs

Q: Why would Anyone desire to get rid of solder without the need for a wick?

Furthermore, utilizing a wick might harm any surface mount technology (SMT) and fine-pitch parts you are dealing with. Or you’re attempting to remove a lot of soldiers, which a wick might not be capable of doing completely.

Q: What equipment is required if I want to avoid using a wick to clean the solder?

You require a hot air cannon, a desoldering instrument, or tweezers, as well as desoldering irons, in order to desolder components. The use of automated desoldering necessitates specific tools and expertise.