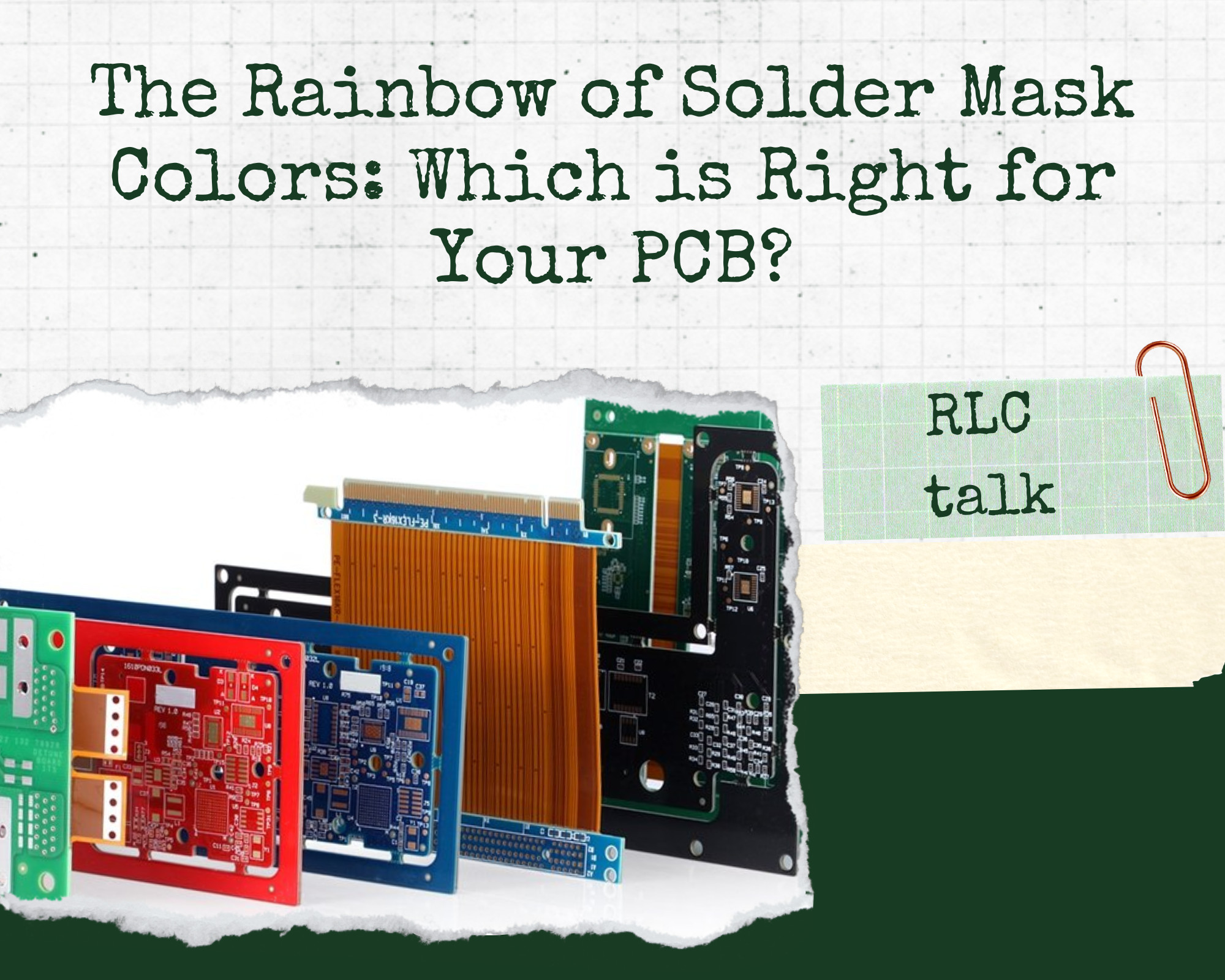

The Rainbow of Solder Mask Colors: Which is Right for Your PCB?

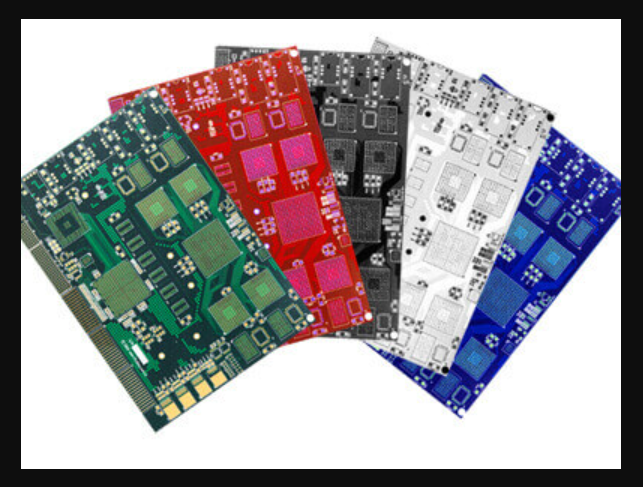

Are you tired of the same old green circuit boards?

It’s time to add some color to your PCBs with solder mask options!

From classic green to vibrant red and blue, the choice is yours.

Keep reading to learn about the various solder mask colors available and discover which one is the best fit for your project.

There are several reasons why different colors are used in printed circuit boards (PCBs). These include identification, aesthetics, reflectivity and heat conduction, and contrast and visibility. The color of a PCB can serve both functional and aesthetic purposes.

Does Solder Mask Color Matter?

When it comes to the functionality of a printed circuit board (PCB), the color of the solder mask is not particularly important. Its primary function is to provide an additional layer of protection for the copper traces on the board, preventing oxidation and solder bridges.

However, the color selected for the PCB can be critical for the purposes of defect inspection. High contrast colors, such as green, offer the best trace visibility and are therefore preferred for PCB prototyping and testing.

In addition to its role in defect inspection, the color of a PCB can serve other purposes as well. For example, some manufacturers use different colors to identify differences between PCBs or to indicate that a PCB is a prototype. This can be helpful in mixed assembly environments and for quality assurance, as well as for maintenance in certain technical applications.

Aesthetics are also a factor to consider when choosing a PCB color. While most people will never see the inside of the devices they use, PCB color variations can provide an eye-catching element for the end user. Some manufacturers use colors to make their products more unique or appealing, especially when paired with translucent exteriors.

Color can play a role in reflectivity and heat conduction, which can be important in certain applications such as LED lighting. By carefully selecting the right PCB color, manufacturers can optimize the performance and appearance of their products.

While the color of a PCB’s solder mask is not crucial for its functionality, it can be important for defect inspection and other purposes such as identification, aesthetics, and reflectivity. By taking the time to carefully consider the best color for their project, manufacturers can create PCBs that not only function well, but also look great.

Eagle vs Altium Designer PCB Software; Best Comparison.

rlc talk

The Spectrum of Solder Mask Colors for Printed Circuit Boards: Pros and Cons

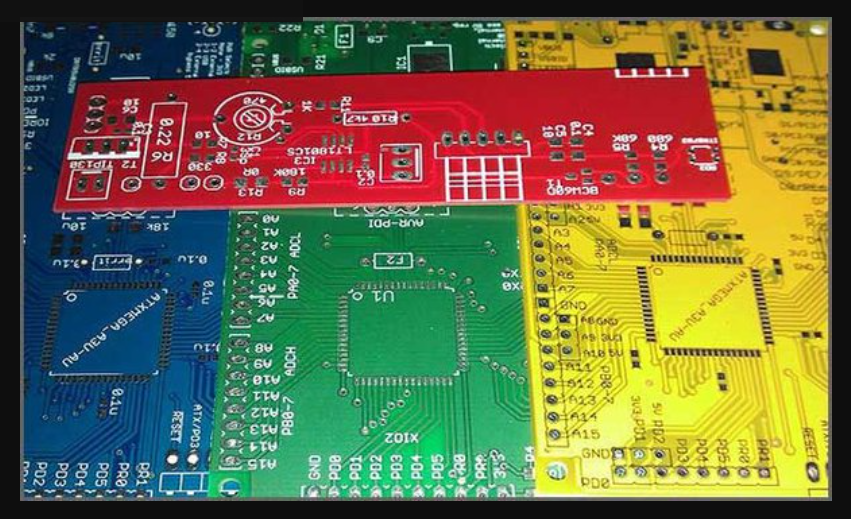

There are several colors available for the solder mask of a printed circuit board (PCB), each with its own unique set of pros and cons. Below, we’ll take a closer look at five of the most common colors: green, red, blue, black, and clear.

Green

Green is the most common color for PCBs and is considered the universal color for circuit boards worldwide. It has one of the highest visual contrasts of any color available, making it desirable for repairs and maintenance.

Green is also one of the least expensive PCB colors, and is widely available at virtually all PCB manufacturing plants in large volumes. However, it should be noted that green has one of the thinnest coats, so it may not be the best choice for applications that require a more durable PCB.

Red

Red is a visually striking option that is often used for designs that showcase interior hardware. While it has become a popular alternative to the standard green PCB, it does have a lower contrast and visibility than green, which can make maintenance and repairs more challenging. Red PCBs may also be more expensive than green ones.

Blue

Blue is another popular choice for PCBs, and like green, it has a high visual contrast. It is also a durable color that is resistant to fading, making it a good choice for outdoor or long-term use. However, blue PCBs may be more expensive than green or red ones, and may not be as widely available.

Black

Black PCBs are a unique and stylish option, and like blue, they are resistant to fading. They also have a high visual contrast, making them suitable for defect inspection and maintenance. However, black PCBs can be difficult to produce, and may be more expensive than other colors.

Clear

Clear PCBs are a transparent option that can be used to showcase the inner workings of a device. They have a high visual contrast, but may not be as durable as other colors. Clear PCBs may also be more expensive to produce, and may not be suitable for all applications.

When choosing a PCB color, it’s important to consider the specific needs of your project, including the intended use, cost, and availability.

While green is a classic and cost-effective choice, other colors such as red, blue, black, or clear can add a unique and stylish element to your PCB design. Ultimately, the best PCB color for your project will depend on your specific needs and preferences.

The color of a printed circuit board’s (PCB) solder mask can be important for a variety of reasons, from defect inspection to aesthetics and reflectivity. While green is the most common and cost-effective choice, other colors such as red, blue, black, and clear can also be used to create unique and stylish PCBs.

It’s important to carefully consider the needs of your project when selecting a solder mask color, taking into account factors such as intended use, cost, and availability. While we’ve covered the pros and cons of the most common PCB colors in this article, there is still room for experimentation and finding what works best for you.

Answers to Your Burning Questions About PCB Solder Mask Colors

What is the purpose of the color of a PCB’s solder mask?

The primary purpose of the solder mask color is to provide an additional layer of protection for the copper traces on the PCB, preventing oxidation and solder bridges.

However, the color of the solder mask can also be important for defect inspection, as high contrast colors like green offer the best trace visibility. In addition, the color of a PCB can serve other purposes, such as identification, aesthetics, and reflectivity.

Do I need Flux with Rosin Core Solder?

Rlc talk

Why is green the most common color for PCBs?

Green is the most common color for PCBs because it has one of the highest visual contrasts of any color available, making it desirable for repairs and maintenance. It is also one of the least expensive PCB colors, and is widely available at virtually all PCB manufacturing plants in large volumes.

Can PCBs be made in any color?

While there is a wide range of colors available for PCBs, not all colors are equally easy or cost-effective to produce. Some colors, such as black and clear, can be more challenging to produce and may be more expensive. It’s important to consider the availability and cost of different PCB colors when selecting one for your project.

Is one PCB color better than the others?

The best PCB color for your project will depend on your specific needs and preferences. While green is a classic and cost-effective choice, other colors such as red, blue, black, or clear can add a unique and stylish element to your PCB design. It’s important to carefully consider the intended use, cost, and availability of different PCB colors when selecting one for your project.

Can multiple colors be used on the same PCB?

Yes, it is possible to use multiple colors on the same PCB. This can be done by applying different solder mask colors to different areas of the PCB or by using multiple layers of solder mask. However, it’s important to consider the complexity and cost of using multiple colors, as well as the impact on trace visibility and other factors.