Do I need Flux with Rosin Core Solder?

Flux would be a crucial ingredient in soldering because it makes the molten solder move more easily and improves the integrity of a soldered junction. Do you continue to apply extra flux when using rosin core soldering that already has a coating in the core? Do I need Flux with Rosin Core Solder?

We’ll look at flux’s function in soldering and answer the question “Do I need Flux with Rosin Core Solder” in this post.

What is soldering?

When two or more metallic components are soldered, a filler metal is melted and poured into the junction to form a strong, permanent bond. To form a solid and long-lasting connection, solder, a filler metal with a lower melting temperature than just the metals getting connected, is utilized. In addition to jewelry, piping, as well as other trades, soldering is frequently employed in electronics and electrical operations.

Due to the need to precisely manage the warmth of the heating element or pistol as well as the quantity of solder utilized, soldering calls for a particular degree of ability and precision. Additionally, it’s critical to thoroughly clean as well as prep the areas being bonded as well as to use the suitable solder plus flux for such a task.

What various core kinds are there for solder?

Here on the basis of its cores, soldiers may be categorized into the following groups.

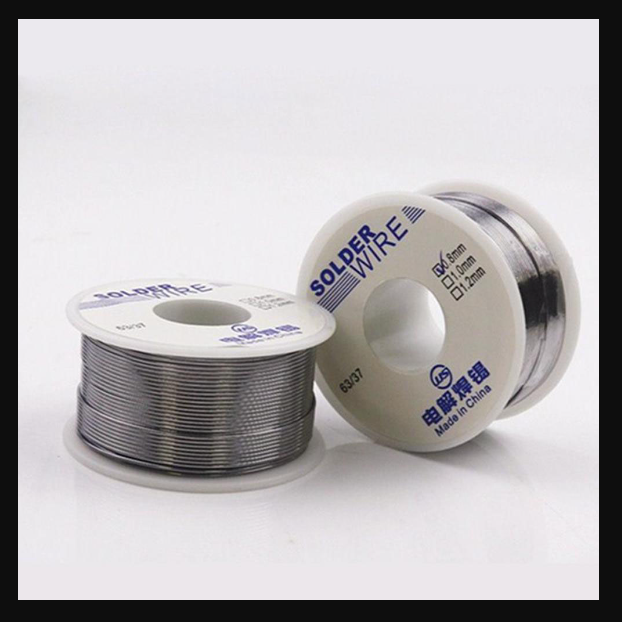

Rosin core solder

This particular solder contains a rosin flux core. It comes in a range of sizes and metals and is frequently used within electrical and electronics operations.

Acid core solder

This particular solder contains an acid flux component. It is frequently used during HVAC as well as irrigation work. Still, it is not advised to be utilized in electrical and electronics jobs since the acid could erode and harm delicate components.

Lead-free solder

Since it is created without lead, this form of soldering is regarded as safer to employ and more favorable to the ecosystem. It comes in a number of alloys and therefore is frequently used in electronics and electrical applications.

Low-temperature solder

In situations in which the parts being bonded are heat-sensitive, this kind of solder, because it has a very low melting point, is frequently employed.

Solder at a high temperature

A long-term and strong connection is needed in situations where this kind of solder, which has a large melting point, is frequently utilized. Heat-sensitive elements shouldn’t be used with it, per recommendation.

Flux: What is it?

In order to optimize the stream of molten solder as well as the integrity of a soldered junction, flux is a material that is employed during soldering. Flux assists in cleaning the soldering surfaces and removing any impurities that may be there, including such compounds or dirt. Additionally, it aids in preventing the development of new pollutants when soldering.

Flux comes in wide different varieties, such as rosin flux, water-soluble flux, and no-clean flux. Flux is a crucial part of soldering that helps to produce joints that are sturdy, dependable, and error-free.

What kinds of flux are there?

Flux can take many different forms, some of which are shown here.

The flux of rosin

This particular flux is created from resin and therefore is frequently utilized in electronics and electrical operations. It is sprayed on the objects getting soldered, whether during or prior to the soldering, and comes in soluble and insoluble formats.

Water-soluble flux

This kind of flux, which may dissolve in liquid, is frequently used during plumbing as well as other situations in which the soldered junction will come into contact with moisture.

No-clean flux

This particular flux is not required to be removed when the soldering procedure is finished. It is frequently employed in both electrical and electronic operations because it leaves a microscopic coating of residue here on the soldered junction that inhibits corrosion.

Activation of flux

This form of flux, which activates when heated, is frequently employed in brazing and soldering operations.

Inactive flux

This kind of flux is frequently utilized in soldering situations in which the existence of active flux can cause problems well with soldering. It isn’t heated up in any way.

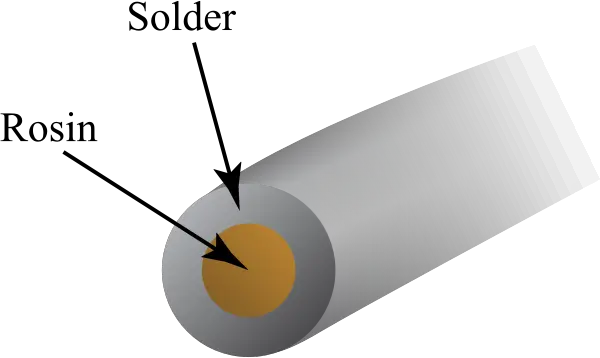

Rosin core solder: What is it?

When working with electronics and electricity, soldering wire with a rosin core is often utilized. It is constructed from a metal alloy, usually tin as well as lead, that has been covered with a rosin flux coating. The rosin flux facilitates the flow of such molten steel while also aiding in the cleaning of the areas being soldered.

For repairing circuit boards, joining wires, as well as other soldering activities, rosin core solder was frequently utilized. For various uses, it comes in a range of sizes and metals. So, do you need Flux with Rosin Core Solder?

Altium Polygon Not Pouring; What Should You Do?

rlc talk

Do I need Flux with Rosin Core Solder?

Rosin core solder does not typically require additional fluxing, as it contains a layer of rosin flux in its core. The rosin flux in the core of the solder is designed to clean the surfaces being soldered and promote the flow of the molten metal.

So, do I need Flux with Rosin Core Solder? In some cases, additional flux may be necessary to ensure a solid and reliable soldered joint. It is vital to use the correct type of flux for the job, as different types of flux are designed for use with different alloys and in different environments. Using the wrong kind of flux can result in a weaker soldered joint or may cause other problems, such as corrosion.

The rosin core solder: How is it fluxed?

The ingredients listed below are necessary to flux the rosin core soldering.

- A soldering gun or even an iron.

- Rosin core solder.

- Flux.

- A fresh, dry sponge is preferred.

These methods should be followed to flux a solder with a rosin core.

- The soldering surfaces should be clean

To cleanse the areas being soldered of any dust, trash, or impurities, use a scrub brush or even a soldering iron, including a cleansing tip. This will contribute to making the soldered junction as solid and dependable as feasible.

- Put the flux in

Apply a little coating of flux here to areas that will be soldered using a swab or flux pen. Ensure that now the flux completely covers your soldering region.

- Warm up the joint

Heat the connection with a soldering iron and soldering pistol. The areas being soldered would be made cleaner, as well as the rosin flux inside the solder’s core would be melted with the aid of heat.

- Include the solder

When the junction is hot sufficient, apply some rosin core solder using the point of such soldering iron as well as a gun and let it melt as well as flow through into the joint. Flux aids in surface preparation for soldering and facilitates the movement of molten steel.

- Let the joint cool off

Before touching or inspecting the junction, let that cool to room temperature after the solder has poured into the connection and is entirely soldered.

Maximizing Conductivity: The Importance of Solder-Coated Wire Conductors

rlc talk