Automated Optical Inspection for Quality Control in Manufacturing

Quality control in manufacturing is essential to ensuring that products meet customer expectations.

Automated Optical Inspection (AOI) is a technology that can be used for quality control in manufacturing. AOI systems detect surface-mount technology (SMT) defects such as missing components, incorrect component orientations, and shorts and open solder joints.

The benefits of using AOI for quality control include increased accuracy and efficiency, reduced inspection costs, and the ability to detect defects that would otherwise be missed.

Read further by reading further about AOI and how it can benefit your manufacturing business.

What is Automated Optical Inspection?

Automated optical inspection (AOI) is a type of machine vision technology used to inspect various products during manufacturing. AOI systems are designed to check items rapidly and accurately for any number of potential defects, making them an essential quality control tool in many industries. In particular, AOI systems are commonly used in printed circuit board assembly (PCBA) production lines to inspect the quality of solder joints.

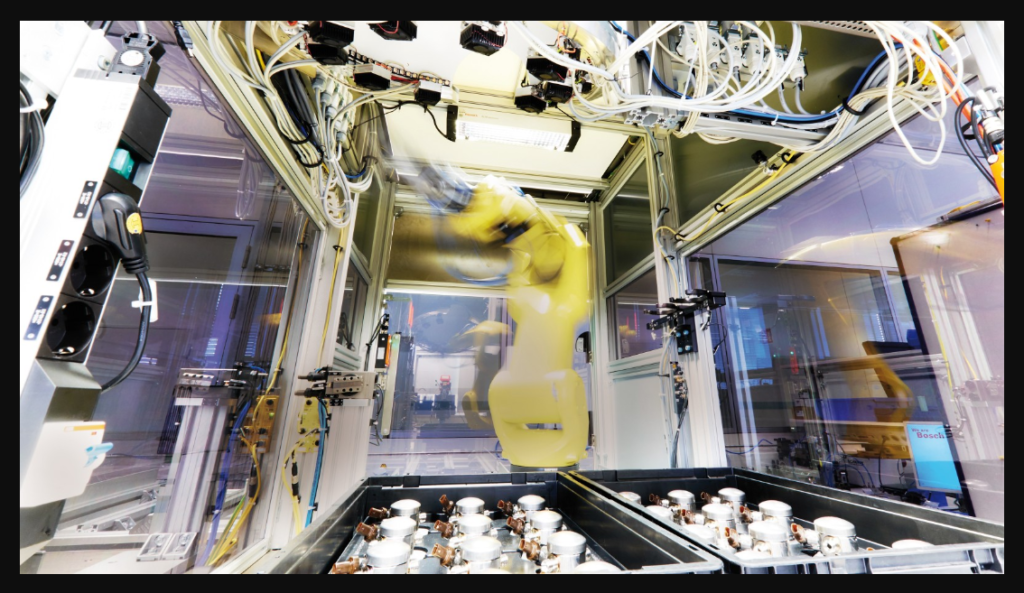

AOI systems typically consist of an illumination system, a camera system, and a computer system. The illumination system illuminates the PCB assembly under inspection with light from one or more directions. The camera captures images of the illuminated PCB assembly from different angles. Finally, the computer analyzes the images to identify any defects in the solder joints.

There are two main types of AOI systems: 2D and 3D. 2D AOI systems use a single camera to capture images from different angles, while 3D AOI systems use multiple cameras to capture images from different perspectives.

What is Chassis Wiring Vs Power Transmission

RLC Talk

Benefits of Using AOI

AOI is an essential tool for quality assurance in producing printed circuit board assemblies (PCBAs). Using cameras and machine learning, AOI can autonomously scan PCBAs and detect two types of failures:

1. catastrophic failures, such as missing components, and

2. quality failures, such as misshapen filets or components that are skewed.

In addition, AOI machines can also detect more familiar dimensional defects such as open circuits, shorts, and thinning of the solder. Mechanical damage is also something that AOI machines can see.

AOI machines are essential because they help to ensure that products are up to par and do not have any defects before they are sent out. With AOI machines, it would be easier to catch all surface and dimensional defects.

Where is AOI used?

AOI systems are used in various industries to inspect items for defects. Some common examples include inspecting printed circuit boards (PCBs) for solder joint defects, examining medical devices for cracks or other manufacturing defects, and checking food products for foreign objects. AOI systems are also used in the automotive and aerospace industries to inspect parts for compliance with specifications.

AOI systems are becoming more and more common as technology continues to improve. They offer several advantages over traditional inspection methods, such as enhanced accuracy and speed, reduced labor costs, and increased throughput. As a result, AOI is quickly becoming the preferred method for inspecting items for defects.

Implementing Automated Optical Inspection.

Automated optical inspection (AOI) is a type of machine vision technology used to inspect various products during manufacturing. A key advantage of using a computerized system is that it can check items rapidly and accurately for any number of potential defects, making them an essential quality control tool in many industries, including automotive, medical device, and electronics manufacturing.

You must first set up the hardware components to implement an AOI system. This includes a camera, light source, frame grabber, and computer. The software components also need to be installed on your computer. These include a capture program for acquiring images from the camera, an analysis program for inspecting the images for defects or other characteristics of interest, and a reporting program for compiling all of the inspection results into a report that can be used by management or quality control personnel.

Each component must be programmed with specific instructions for the system to work correctly. The cost of setting up an AOI system varies depending on the size and complexity of the system.

Small systems can cost as little as $10,000, while larger systems can cost over $1 million. However, the savings achieved by reducing scrap and rework costs typically offset the cost.

How To Import Gerber Files In EasyEDA?

RLC Talk